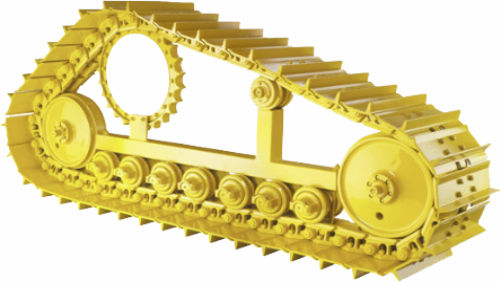

An extensive range of Undercarriage parts for a variety of equipment including Bulldozers, Excavators, Drill Machines is manufactured by us. We have Track Groups / Track Shoe Assemblies, Track Link Assemblies, Track Shoes, Track Shoe Bolt and Nuts, Track Rollers, Idlers, Sprockets and Sprocket Segments.

We manufacture track chains ranging from 135mm to 318 mm link pitch consisting of traditional dry and sealed excavator track chains to lubricated Salt Chains for high performance mining dozers. TPI track links, pins and bushings are specifically heat-treated via induction to achieve hardness levels pre-determined by our qualified engineers for maximum resistance during operation in all terrain conditions. Sealed link assemblies are fitted with seals and sealed with synthetic oil for lubrication purposes to reduce damage from harmful dirt particles and enhance operational wear life.

We Manufacture single, double flange track rollers and carrier rollers with operational weight from 6 tons up to 200 tons. Majority of the rollers are forged and welded using friction welding technology for prolonged operation life and produced according to original equipment manufacturer specifications.

We offer a large range of Sprockets/Segment Group from 6 tons to 200 tons to cover most heavy equipment in use today. All segments are forged, machined and heat treated to produce the best quality.

All Bolt on sprockets are steel casted and heat treated method to achieve the pre determined surface and inner core hardness level.

We have an extensive range of Idlers to suit most makes and models. Our Idlers come in either steel-casting or fabricated welding and are fitted with reinforced side walls.

Cast Idler groups are now manufactured for most Bulldozer and Excavator applications using special heat treatment and hardness techniques on running surface to extend wear life.